SC Solutions has won Small Business Innovation Research (SBIR) Phase III funding from the U.S. Department of Agriculture’s (USDA’s) Meat and Poultry Processing Research and Innovation (MPPRI) program to develop a tool to accurately estimate the fat content of meat being processed. This estimation will be performed in real time using optical image analysis while the meat is being processed on the conveyor. SC will adapt an existing image analysis technology (SC-MDD™, developed earlier with SBIR Phase II funding) for this application. This tool will provide a cost-effective solution to a key challenge to the meat processing sector which must meet quality and regulatory standards and benefit the supply chain resilience of small and mid-size meat and poultry processors.

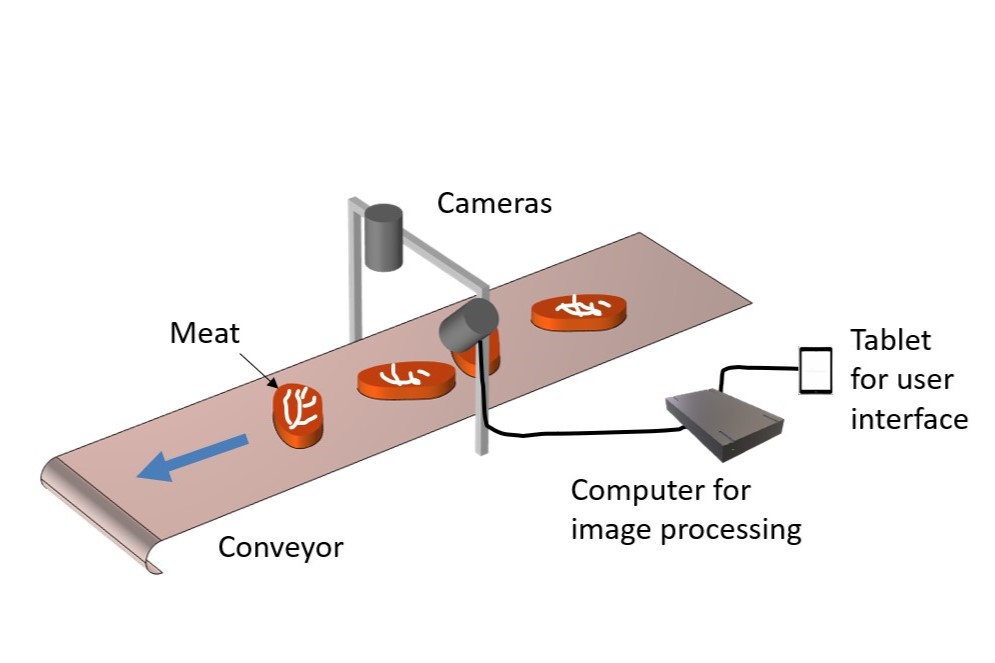

SC will work closely with our meat processing partner, Lorentz Meats, Cannon Falls, MN to customize the technology for their meat processing environment. All hardware components will be commercial off-the-shelf (COTS) items including high-resolution cameras and suitable packaging to operate in harsh environments, as well as sufficient computing resources to process images in real-time. Software libraries associated with the hardware, as well as custom software to be developed, will be integrated to create a data collection, processing and assimilation system that will be used to train a suitable machine learning (ML) algorithm (e.g., deep neural network) to detect and estimate the lean-to-fat meat ratios. The tool will employ a flexible, modular architecture that will function either with conveyor belts or on manual processing lines. The effectiveness of the technology will be demonstrated at Lorentz Meats’ processing plant.

SC will work closely with Larta Institute of Los Angeles, CA, to commercialize the resulting tool prototype. Successful commercialization will assist in significantly increasing accuracy in meat classification by fat and thus decrease the waste and help meet quality and regulatory requirements. Lorentz Meats will immediately benefit from integrating the proposed tool into their meat processing line. Subsequently, use of this inexpensive real-time image analysis tool will be extended to other related applications by small and medium meat processors nationally.