Model-Based Control Solutions

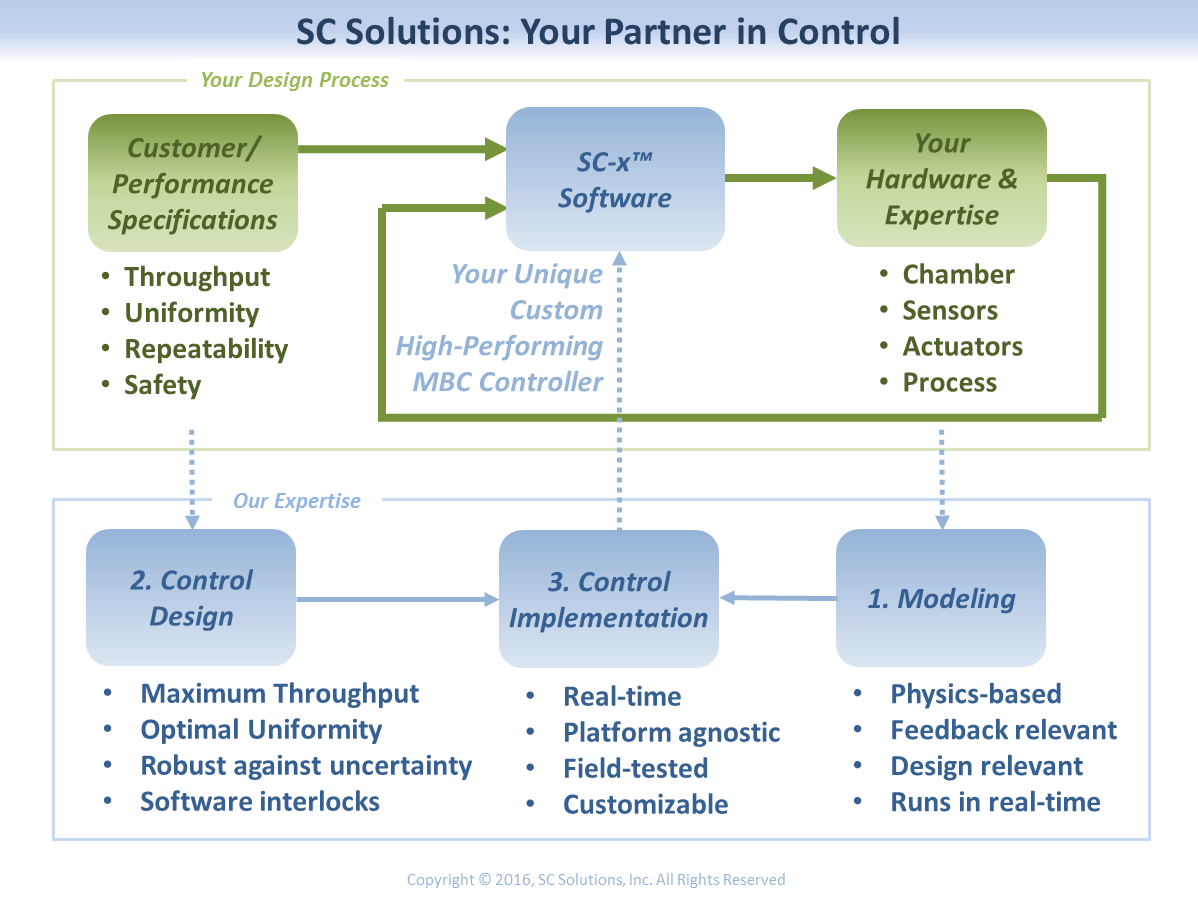

SC Solutions designs and implements process control solutions for semiconductor and advanced materials manufacturing. Our Model-Based Controller (MBC) software products include both real-time and run-to-run controllers. These high-performance feedback and feedforward controllers have been proven in the field for over a decade. Our model-based control solutions are customized for each equipment design and are seamlessly integrated into each customer’s software framework. In addition, we perform innovative work in basic control systems research.

What is a Custom Model-based Controller (MBC)?

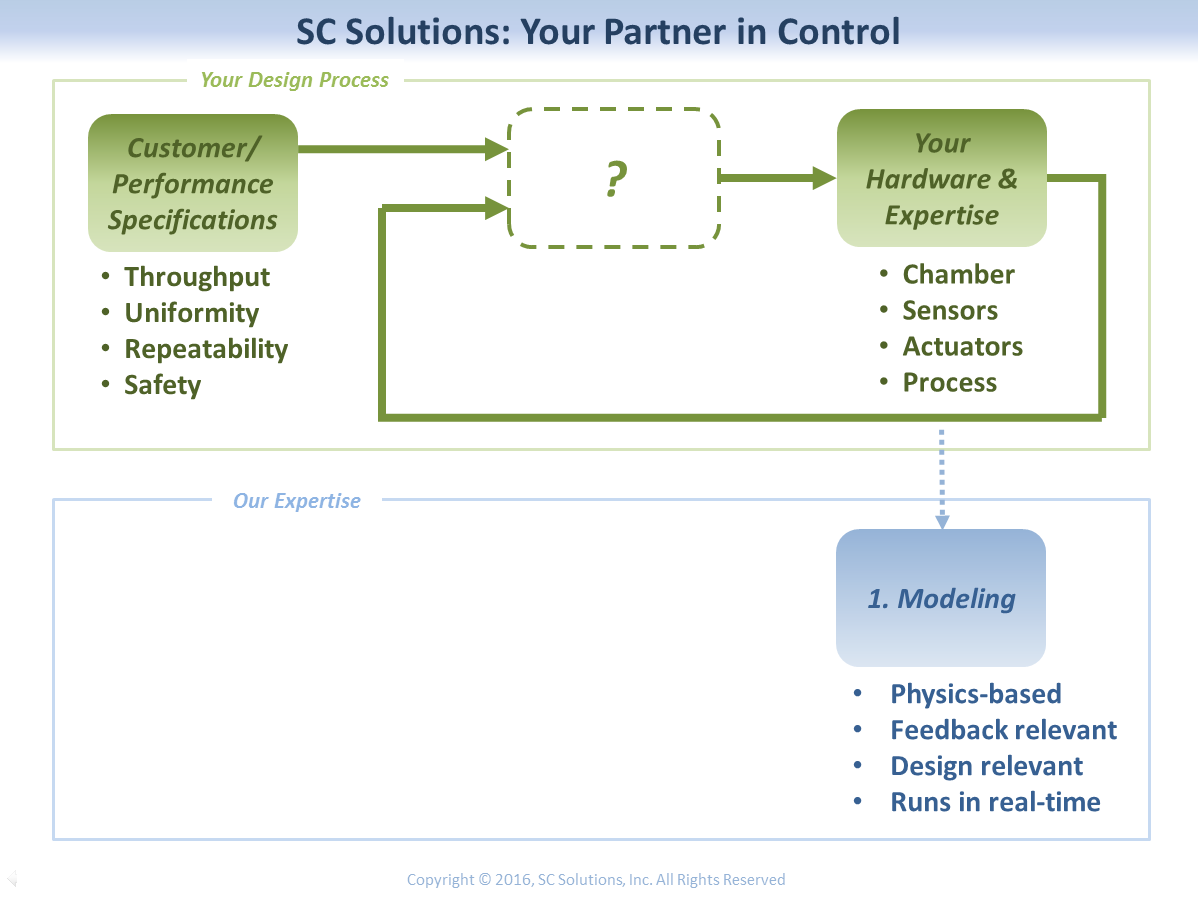

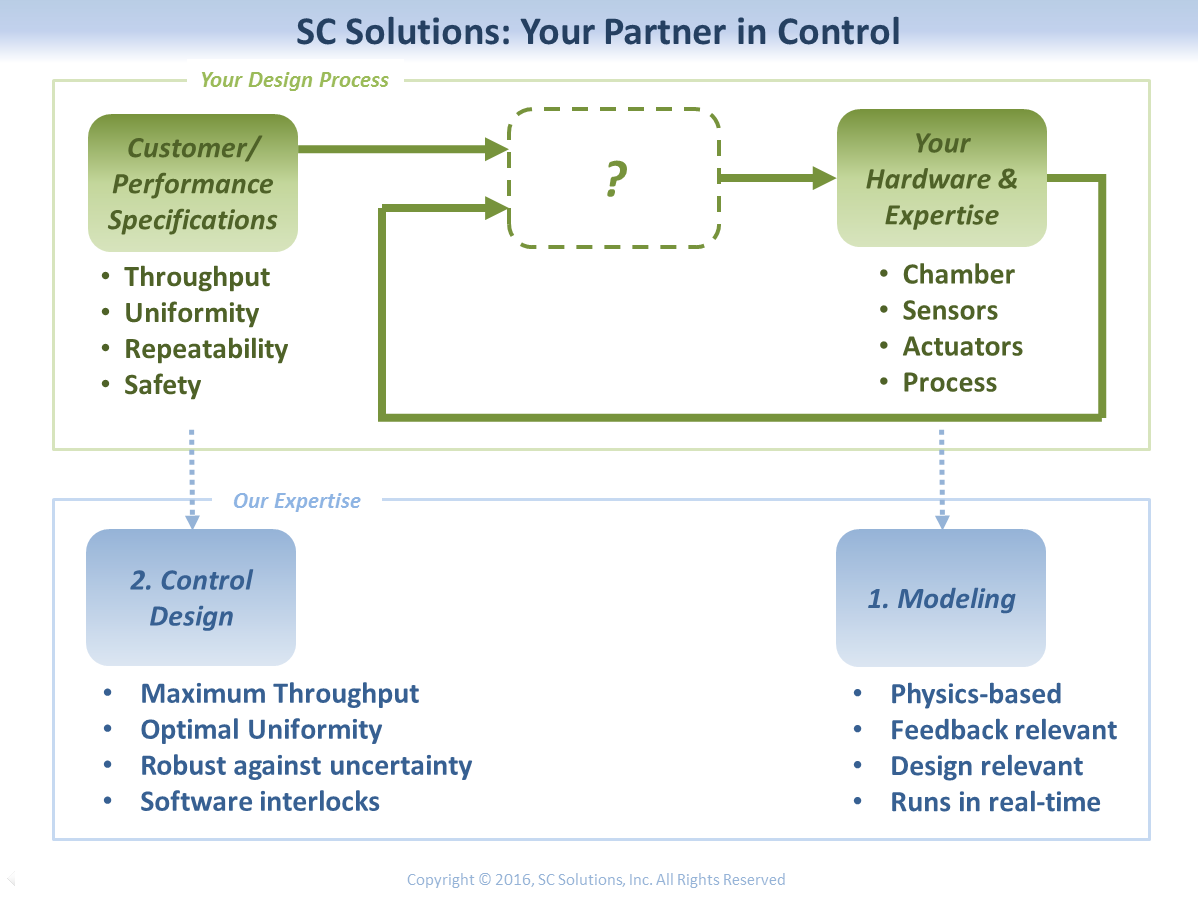

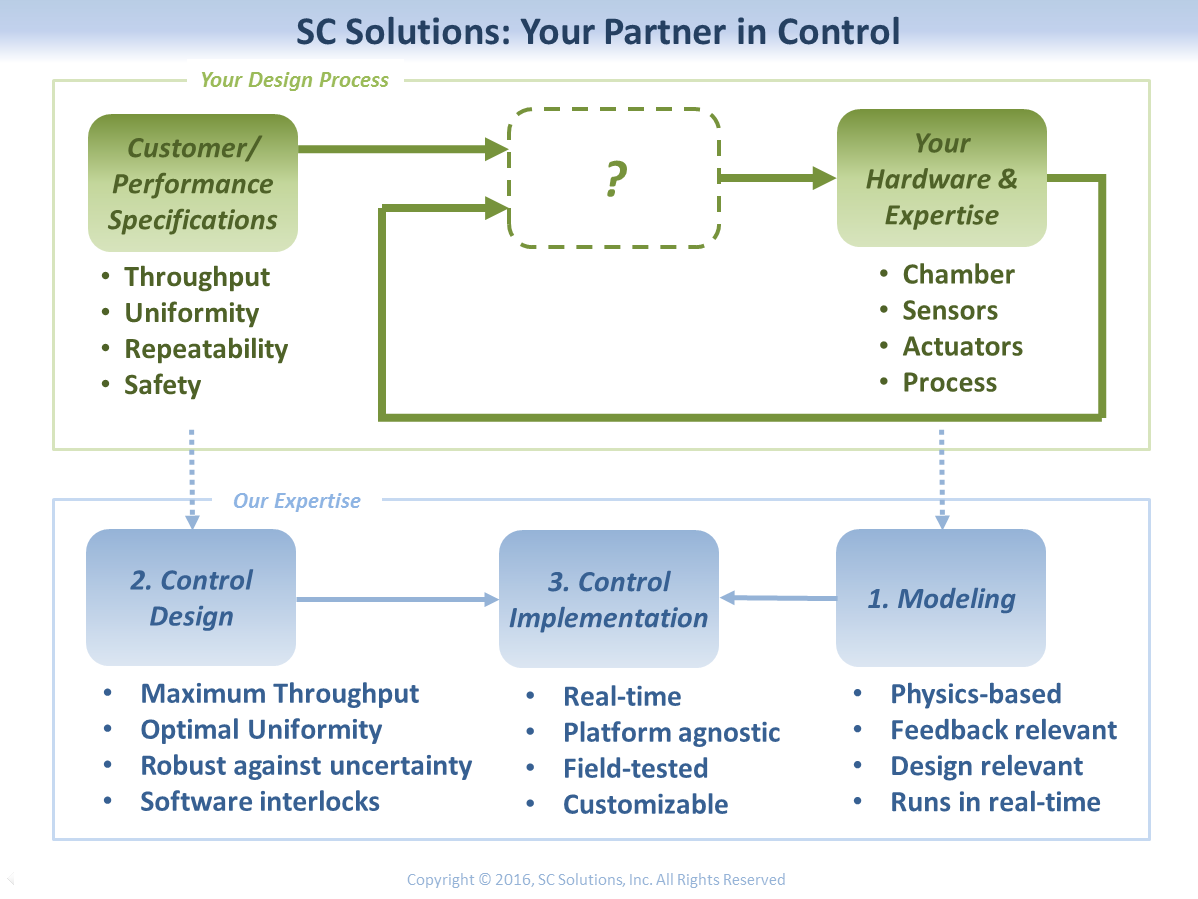

MBC Design is the cornerstone of SC Solutions’ control design technology. An accurate, physics-based model is incorporated into the controllers (and often in sensor signal processing algorithms) as shown in the above schematic. The first step in this proven technology is the development of a custom physics-based computer model of the system to be controlled. The model (generally nonlinear) is then validated using experimental data from the system. The order and the complexity of the model depends on the application, but are typically large at the validation stage. A reduced-order model that can simulate equipment operation faster than real time is then constructed for use in MBC design. For a more detailed description, please visit our Model-based Control and Equipment Design page.

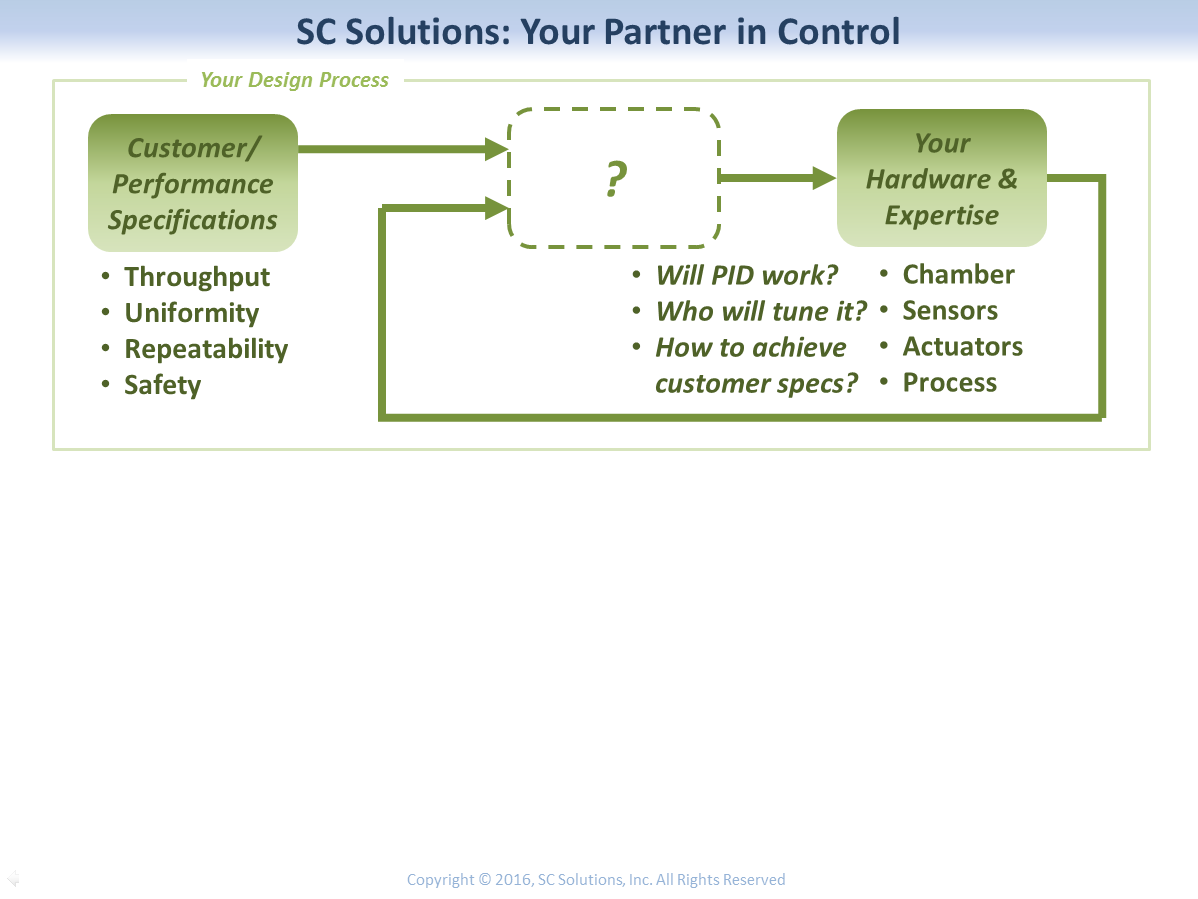

Why would I need a Model-based Controller and how does it compare to a PID controller?

An MBC controller has several advantages over a PID controller including the ability to extract maximum performance out of the system, greater robustness, ability to provide physical insight into system performance, greater cost efficiency, and reduced time-to-market. These advantages are particularly evident in the case of complex, non-linear, Multi-Input Multi-Output (MIMO) systems with strong interaction between the various system inputs and outputs, as illustrated by our case study on the relative performance of PID versus model-based control. For those systems, MBC controllers provide the competitive edge needed to meet today’s manufacturing challenges. Please visit our MBC products page for more details.

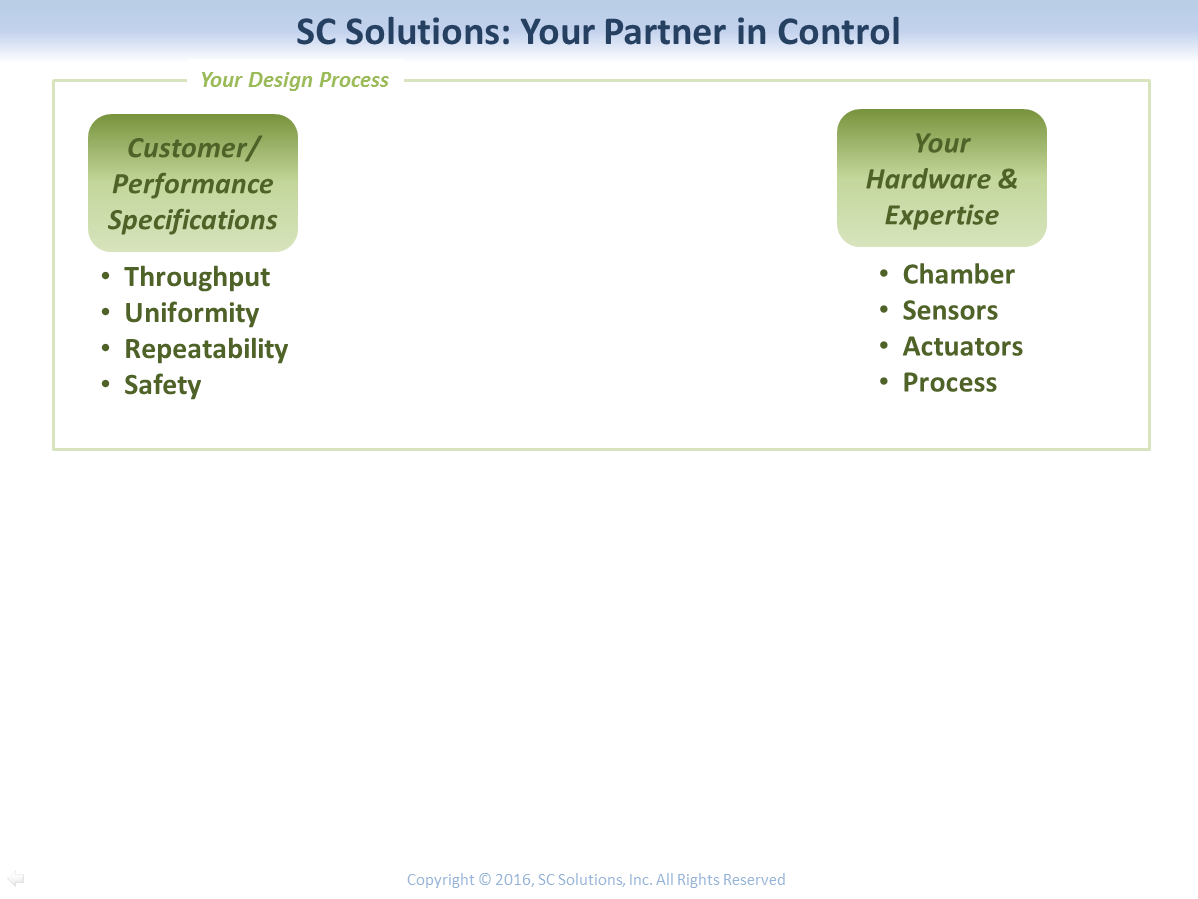

What would the development of a Model-based Controller look like for my system?

The first step in developing an MBC is to build a physical model of the relevant part of your equipment such as the reactor of the wafer processing equipment. The geometry information is generally supplied to SC Solutions as a CAD file in a common format such as STEP. Together with associated material properties, a high-order model is developed and calibrated with open-loop experimental data. A reduced-order model is then developed from the validated high-order model for use in control system design. A feedback controller is then designed and the closed-loop control system is first evaluated in simulation. Once the performance meets (or exceeds) specification, the feedback controller is used to control the actual system and data is collected. Based on the performance, the controller is tuned or modified as part of the iterative process of controller development. The MBC approach conveniently minimizes the need for access to the equipment since the latter comes at a premium. We provide a clear and easy to use software interface to our controllers, including the ability to tune and update the controller without the need for recompiling code, reducing your QA cycle time.

What computer hardware and operating systems do you support?

Our custom control software can be compiled on a wide range of Real Time Operating Systems (RTOS) and hardware platforms. Our software is often incorporated into our customers’ framework and compiled with their code. However, we also deliver control software as stand-alone executables or even as boxes on a hardware-software platform of our customer’s choice.

How much does it cost?

Our business model is based on licensing our control software on a per unit license fee for the software shipped on our customer’s equipment. In addition, there will be some NRE cost for the initial modeling and MBC development effort. We provide technical support to our customers with regard to use of the controller software, and provide upgrades as needed.