To meet the need for real-time profile control (RTPC) on Applied Materials 200mm Mirra® CMP tools, Applied turned to its long-time partner, SC Solutions, Inc. Together, the two companies tackled a variety of technical issues. Read this article in the July issue of Applied Materials’ NANOCHIP FAB Solutions Technology Journal to learn more about how SC Solutions and Applied Materials overcame new challenges when upgrading 200mm Chemical Mechanical Planarization (CMP) equipment to 300mm state-of-the art technology.

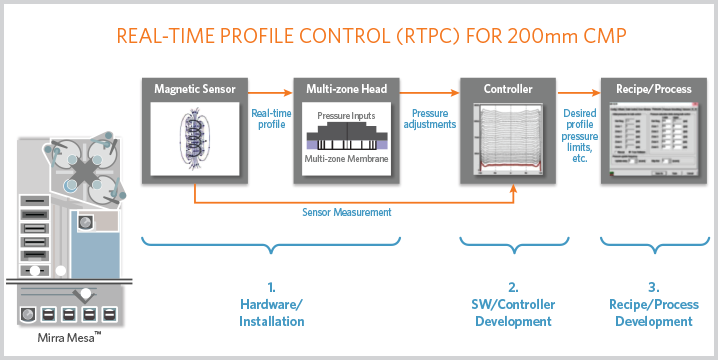

The two companies have collaborated for many years on solutions for Chemical Mechanical Planarization (CMP) equipment for semiconductor manufacturing. Twenty years ago, the Semiconductor Industry was moving from 200mm to 300mm wafers to increase production and save production cost. Today, the industry is revamping the 200mm wafer industry because of high demand of low-cost chips in phones, cars, appliances, etc. Applied Materials’ 300mm CMP has successfully used Real-Time Profile Control (RTPC™) to control polishing uniformity of metal layers based on measuring its thickness in real-time using a magnetic sensor. The increased interest in 200mm, as well as new applications like thick copper and the ability to run one recipe for multiple applications under varying process conditions, have motivated the integration of RTPC™ into Applied Materials’ 200mm Mirra® CMP system.